Here, applying physicochemical and electrochemical ex situ and in situ characterizations, the effect of Co and Mn on the mechanical properties of the Ni-rich material are thoroughly investigated.

ENERGY DENSITY OF NMC CATHODE MATERIALS CRACK

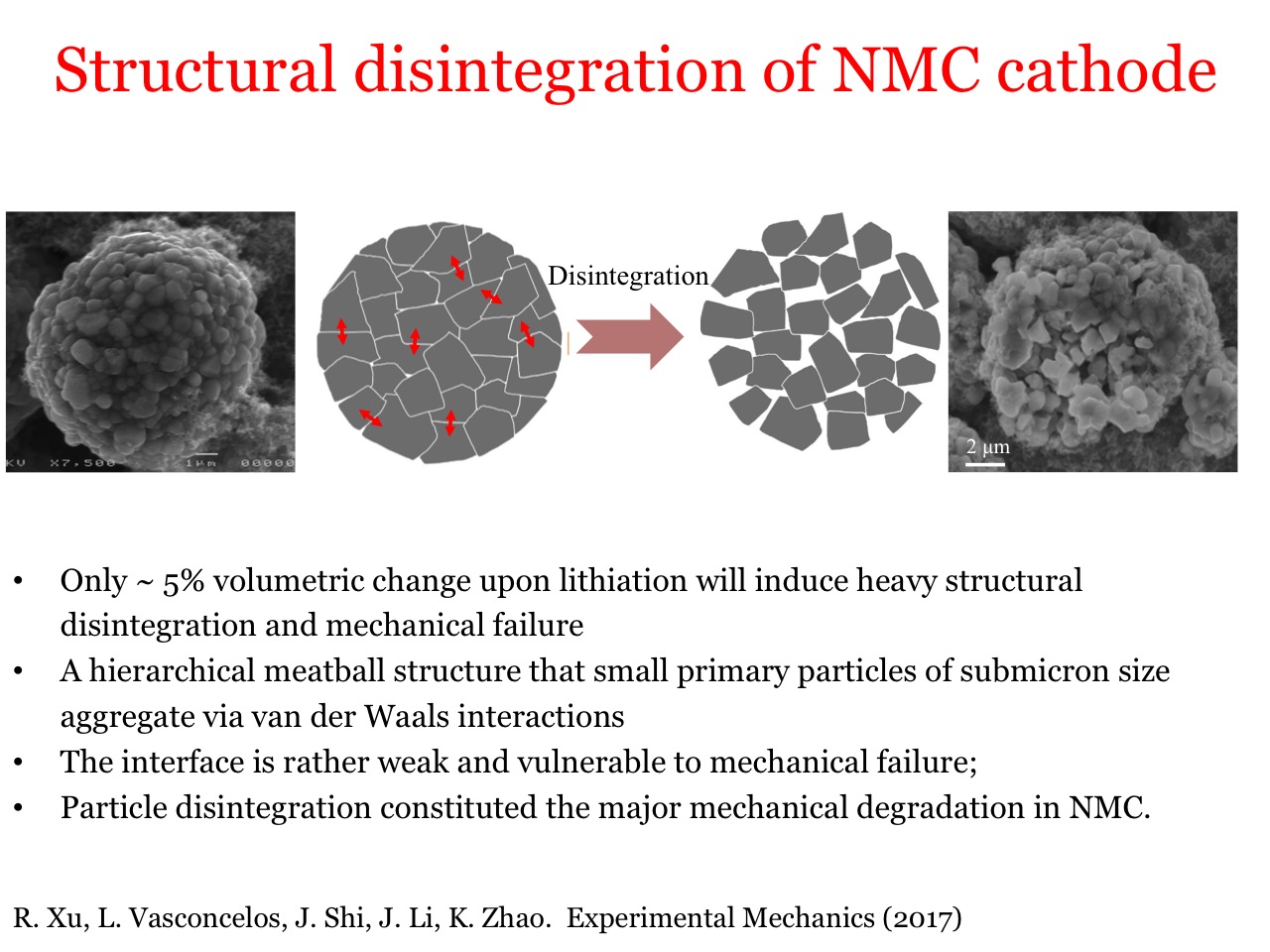

Indeed, the detrimental effects generated from the crack formation are not yet entirely addressed. If the announcements in Europe are actually implemented at the targeted rate, NMC battery cell production in Europe would even be larger than in China by 2030.Mechanical integrity issues such as particle cracking are considered one of the leading causes of structural deterioration and limited long-term cycle stability for Ni-rich cathode materials of Li-ion batteries. and Europe will gain a significant share of global production by the end of the decade. At least for NMC battery cell production, the U.S. In the case of NCA cathodes, the production of Samsung SDI and Panasonic is particularly relevant.Ĭurrently, China dominates both NMC and LFP battery cell production. In the production of NMC cathodes, manufacturers such as CATL, but also the Korean companies Sk On and LGES are active. (CATL) account for a large share of LFP cathode production. In parallel, LFP cell production in Europe will also slowly increase and gain relevance.Įurope could produce more NMC cathodes than China in 2030Ĭhinese manufacturers such as China Aviation Lithium Battery (CALB) and Contemporary Amperex Technology Co. In the course of the coming decade, European NMC battery cell production will therefore also account for an increasingly relevant share. In Europe, the production of NMC battery cells will clearly predominate in 2030. In the USA, the influence of Tesla and the NCA cathode material, used more or less exclusively by this manufacturer, is also clearly visible. Whereas in Europe and the USA the high-performance and more expensive luxury vehicles are particularly well represented in the market, in China there are also many small cars with LFP cell chemistry. The production of the individual cathode materials is market-driven. This points to a clear advantage of LFP batteries.

In stationary storage, the compactness of the battery does not play a central role, since there are no strict space restrictions as in electric vehicles. If price is the top priority, LFP-based batteries are used, for example, for larger vehicles such as buses or heavy-duty transport or for small vehicles. In electric vehicles, where achievable speed and the ability to drive longer distances are prioritized over price (upper class segment), NMC and NCA technologies seem to be more popular due to their higher performance. This is due, for example, to supply bottlenecks caused by the war in Ukraine and the associated speculation about supply shortages. The price of nickel has also risen sharply at times in recent years. Cobalt mining is complex and therefore expensive. NMC and NCA batteries can have higher costs due to limitations in the availability of raw materials. However, LFP batteries have a lower energy density and therefore require more space to provide the same amount of energy. They are also more resistant to high temperatures. In terms of safety, LFP technologies offer advantages over more flammable NMC and NCA materials. Advantages and disadvantages of the individual active materials For an NMC cathode, reducing the cobalt content while increasing the nickel content results in a cost reduction and energy density increase. For example, the energy density of an LFP cathode can be increased with the help of manganese (LMFP cathode). Furthermore, both LFP and NMC batteries offer development opportunities. They have different advantages and disadvantages that make these technologies more or less attractive depending on end-use requirements. First, LFP and NMC/NCA cathodes are complementary technologies. This can be attributed to several aspects. Nevertheless, the market shares of these two technologies are expected to remain high until the end of the decade. Global production of battery cells will increase sharply in the coming years, and cathode materials will be newly and further developed.

0 kommentar(er)

0 kommentar(er)